| User Login |

|

| Search |

|

| Categories |

|

|

|

|

Products  |

|

|

|

|

|

| |

| |  UTX750B X ray fluorescence spectrometer UTX750B X ray fluorescence spectrometer |  | | Product Name: UTX750B X ray fluorescence spectrometer

Order number:

Optional accessories: no

Inquiry:

Detailed description

One, application field

UTX750B is a versatile X ray fluorescence spectrometer, suitable for:

1, RoHS detection

The EU RoHS directive is restricted by the Cr, Hg, Pb, Cd, Br, Cl, I and other elements of the detection

2, coating testing

Suitable for testing the larger size of the hardware, connectors, electrical connector plating, plating, plastics, PCB, ABS magnesium alloy electroplating. Particularly suitable for thin Au, Ag, Pd and other precious metal plating.

Hardware, connectors, electrical connector plating Au, Ag, Sn, Ni, Cu, Zn, Cr, NiP, SnPb, SnCu, ZnNi, AuPdNi such as alloy;

PCB Au, Ag Cu, electroplating, Ni, NiP, SnPb alloy;

Plastic, ABS, magnesium alloy electroplating Au, Ag, Sn, Ni, Cu, Zn, Cr, NiP etc..

3, plating bath analysis

Electroplating solution of Au, Ag, Cu, Ni, Cr, Zn, Sn concentration was detected, and the impurity elements Ag, Cu, Ni, Cr, Zn, Sn, Fe, Co, Mn, Sb analysis.

4, alloy analysis

Stainless steel in Fe, Cr, Ni, Mo and other components

Alloy steel in Fe, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Nb, Mo, Sn, Sb, W, Pb and other components

Copper alloy in Cu, Zn, Fe, Cr, Ni, Cu, Zn, Sn, Sb, W, Pb, and other ingredients

Zinc alloy in Zn, Cu, Fe, Cr, Mn, Ni, Cu, Zn, Sn, Sb, Pb, W, and other ingredients

Solder in Sn, Fe, V, Cr, Ni, Cu, Zn, Nb, Sb, W, Pb and other components

5, precious metal identification

Gold jewelry testing purity and impurity Ag, Ni, Cu, Zn, Cd, Y, Zr, Rh, Pd analysis

Platinum jewelry testing purity and impurity Ag, Ni, Cu, Zn, Cd, Y, Zr, Rh, Pd, Au analysis

Palladium jewelry testing purity and impurity Ag, Ni, Cu, Zn, Cd, Y, Zr analysis

Silver jewelry testing purity and impurity Fe, Ni, Cu, Zn, Cd, Sn analysis

6, food and safety inspection

The daily food trace elements Fe, Ca, Zn, Cu, Pb, Cd, Ni analysis

Analysis of the effective components in various supplements such as Ca oral liquid on the content of Ca, Zn oral liquid on Zn content

Tea discrimination : according to the different origin of the trace elements in tea of different tea varieties, discrimination and authenticity

7, environment detection

Gasoline, diesel, kerosene and other content in Pb, As, Cd and other elements of the detection

Analysis of water quality analysis, water, sewage, river water, groundwater, drinking water Fe, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Nb, Mo, Sn, Sb, W, Pb, Hg, Cd and other elements

Two, product characteristics

1, from Al to U rapid element analysis, metal plating thickness detection

In 2, the detection sensitivity of 1ppm 99.99%; 0.005um to 35um coating

In 3, 15-20 times CCD color system was used for sample image observation

4, in a variety of shapes and specifications of the collimator can be chosen

In 5, a variety of filtering mechanism, a variety of specifications of filters for different samples

In 6, high resolution of SIPIN detector, improve the measurement sensitivity

In 7, the detector of electric refrigeration, without liquid nitrogen

In 8, large sample chamber with precision regulating electric sample table, can measure large to small samples of various sizes

In 9, FP basic algorithm software

In 10, the flexible application of analysis software

11, simple installation, fast instrument

Three, technical indicators

|

High-voltage power supply |

|

|

Input voltage |

24VDC±10% |

|

|

Output voltage |

0-50kV |

|

|

Output current |

0-2.0mA |

|

|

Output precision |

0.01% |

|

|

Remarks |

Software automatic detection function |

|

|

X ray tube |

|

|

X ray tube target |

W target, Rh, Mo, Ag, Cr target optional |

|

|

X ray tube window |

Nylon window |

|

|

Electrical parameters |

50W、4-50kV,0-1000uA |

|

|

Cooling mode |

Silicone grease cooling |

|

|

Service life |

15000-20000h |

|

|

Detector |

|

|

Detection range |

Al19-U92 |

|

|

Resolution |

FWHM 139eV |

|

|

The detection window |

Be,Window area:5-25mm2 |

|

|

Thickness |

0.5-5mm |

|

|

Spectral processing system |

|

|

Processor type |

Full digital 32-bit3 DSP |

|

|

The number of spectral channels |

256,512,1024,2048 choice |

|

|

Counting rate |

More than 100000cps |

|

|

Energy range |

500eV-40960eV |

|

|

Dead time |

<3% |

|

|

|

Light path system and sample observation |

|

|

Collimator system |

φ8mmφ8mmφ8mmφ2mmφ0.5mm Switchable |

|

|

Minimum measuring point size |

φ0.6mm |

|

|

Focusing system |

Laser focus |

|

|

Filter |

A variety of filter ( Ni, Cu, Mo, Al, Ti ) to choose |

|

|

Sample observation system |

The 3000000 pixel high-definition CCD camera, 20 times optical zoom. |

|

|

RoHS measuring index |

Analyses of 1ppm-99.99%

Precision : the relative standard deviation is less than 5% ( content is greater than 500ppm )

Accuracy: the relative error less than 5% ( content is greater than 500ppm ) |

|

|

Thickness indicator |

Analysis of range: 0.01-35um

Precision and accuracy: the first layer of the relative standard deviation is less than 5%

Second layer relative standard deviation less than 10%

Third layer relative standard deviation less than 15% |

|

|

Plating bath analysis |

Analysis of range: 0.01g-1000g / L

Precision : the relative standard deviation is less than 5%.

Accuracy: the relative error less than 5% |

|

Sample room |

|

|

Sample room interior space(mm) |

(W x H x D):450×90×400mm |

|

|

Sample size |

(宽×深):250×275mm |

|

|

Sample table bearing weight |

≤5kg |

|

|

The test sample size |

W x H x D:440×80×390mm。 |

|

|

Sample table control |

Automatic 3D X-Y-Z sample stage |

|

|

Work bench mobile |

X=200±5、Y=200±5、Z=80±5mm |

|

|

Worktable moving precision |

0.005mm |

|

|

|

Computer and software |

|

|

|

Control computer |

Lenovo brand QitianM7150, 1GB memory, 160G hard disk |

|

|

|

Monitor |

Lenovo 17 inch LCD display |

|

|

|

Operating system |

WindowsXP、OEM simplified Chinese Edition |

|

|

|

Report results |

Word、Excel format |

|

|

|

Software |

RoHS detection software, coating thickness software, element analysis software |

|

|

|

Types of software |

Fundamental parameter method of FP software |

|

|

|

Software language |

Simplified Chinese, traditional Chinese, English, other |

|

|

|

Spectrum display |

Automatic peak qualitative, KLM markers, spectral overlapping comparison |

|

|

|

Spectral processing |

Total intensity, net intensity, background intensity; the whole area, net area, much element fitting, Gauss fitting; logarithmic spectrum |

|

|

|

Data analysis |

The basic parameters, basic pattern, without standard sample test, peak position correction, substrate amendment |

|

|

Weight and size |

|

|

The main body of the device size(mm) |

W 580×H 635×D 770mm |

|

|

Body weight |

About 80kg |

|

|

The environment of the use |

|

|

Working environment |

Temperature 15-250C,Humidity 40-70%RH |

|

|

Power supply system |

Single-phase 220V±10%,Working voltage in allowed range |

|

|

Other |

1. Don’t close to generate strong magnetic field, electric field, high frequency device

2. Reducing vibration

3. Less dust, low humidity, no corrosive gas

4. No direct sunlight

5. As the earthquake countermeasures, to consider the fixed device |

|

|

|

|

|

|

|

|

| |

|  | |  UTX760X ray fluorescence spectrometer UTX760X ray fluorescence spectrometer |  | | Product Name: UTX760X ray fluorescence spectrometer

Order number:

Optional accessories: no

Inquiry:

Detailed description

One, Product brief introduction

UTX760 is a versatile X ray fluorescence spectrometer, suitable for:

1, RoHS detection

The EU RoHS directive is restricted by the Cr, Hg, Pb, Cd, Br, Cl, I and other elements of the detection

2, coating testing

Suitable for testing the larger size of the hardware, connectors, electrical connector plating, plating, plastics, PCB, ABS magnesium alloy electroplating. Particularly suitable for thin Au, Ag, Pd and other precious metal plating.

Hardware, connectors, electrical connector plating Au, Ag, Sn, Ni, Cu, Zn, Cr, NiP, SnPb, SnCu, ZnNi, AuPdNi such as alloy;

PCB Au, Ag Cu, electroplating, Ni, NiP, SnPb alloy;

Plastic, ABS, magnesium alloy electroplating Au, Ag, Sn, Ni, Cu, Zn, Cr, NiP etc..

3, plating bath analysis

Electroplating solution of Au, Ag, Cu, Ni, Cr, Zn, Sn concentration was detected, and the impurity elements Ag, Cu, Ni, Cr, Zn, Sn, Fe, Co, Mn, Sb analysis.

4, alloy analysis

Stainless steel in Fe, Cr, Ni, Mo and other components

Alloy steel in Fe, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Nb, Mo, Sn, Sb, W, Pb and other components

Copper alloy in Cu, Zn, Fe, Cr, Ni, Cu, Zn, Sn, Sb, W, Pb, and other ingredients

Zinc alloy in Zn, Cu, Fe, Cr, Mn, Ni, Cu, Zn, Sn, Sb, Pb, W, and other ingredients

Solder in Sn, Fe, V, Cr, Ni, Cu, Zn, Nb, Sb, W, Pb and other components

5, precious metal identification

Gold jewelry testing purity and impurity Ag, Ni, Cu, Zn, Cd, Y, Zr, Rh, Pd analysis

Platinum jewelry testing purity and impurity Ag, Ni, Cu, Zn, Cd, Y, Zr, Rh, Pd, Au analysis

Palladium jewelry testing purity and impurity Ag, Ni, Cu, Zn, Cd, Y, Zr analysis

Silver jewelry testing purity and impurity Fe, Ni, Cu, Zn, Cd, Sn analysis

6, food and safety inspection

The daily food trace elements Fe, Ca, Zn, Cu, Pb, Cd, Ni analysis

Analysis of the effective components in various supplements such as Ca oral liquid on the content of Ca, Zn oral liquid on Zn content

Tea discrimination : according to the different origin of the trace elements in tea of different tea varieties, discrimination and authenticity

7, environment detection

Gasoline, diesel, kerosene and other content in Pb, As, Cd and other elements of the detection

Analysis of water quality analysis, water, sewage, river water, groundwater, drinking water Fe, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Nb, Mo, Sn, Sb, W, Pb, Hg, Cd and other elements

Two, product characteristics

1, from Al to U rapid element analysis, metal plating thickness detection

In 2, the detection sensitivity of 1ppm 99.99%; 0.005um to 35um coating

In 3, 15-20 times CCD color system was used for sample image observation

4, in a variety of shapes and specifications of the collimator can be chosen

In 5, a variety of filtering mechanism, a variety of specifications of filters for different samples

In 6, high resolution of SIPIN detector, improve the measurement sensitivity

In 7, the detector of electric refrigeration, without liquid nitrogen

In 8, large sample chamber with precision regulating electric sample table, can measure large to small samples of various sizes

In 9, FP basic algorithm software

In 10, the flexible application of analysis software

11, simple installation, fast instrument

Three, technical indicators

|

High-voltage power supply |

|

|

Input voltage |

24VDC±10% |

|

|

Output voltage |

0-50kV |

|

|

Output current |

0-2.0mA |

|

|

Output precision |

0.01% |

|

|

Remarks |

Software automatic detection function |

|

|

X ray tube |

|

|

X ray tube target |

W target, Rh, Mo, Ag, Cr target optional |

|

|

X ray tube window |

Nylon window |

|

|

Electrical parameters |

50W、4-50kV,0-1000uA |

|

|

Cooling mode |

Silicone grease cooling |

|

|

Service life |

15000-20000h |

|

|

Detector |

|

|

Detection range |

Al19-U92 |

|

|

Resolution |

FWHM 139eV |

|

|

The detection window |

Be,Window area:5-25mm2 |

|

|

Thickness |

0.5-5mm |

|

|

RoHS measuring index |

|

|

Analysis range |

1ppm—99.99% |

|

|

Precision |

The relative standard deviation below 5% ( content is greater than 500ppm ) |

|

|

Degree of accuracy |

Relative error below 5% ( content is greater than 500ppm ) |

|

|

Thickness indicator |

|

|

Analysis range |

0.01um—35um |

|

|

The first layer |

The relative standard deviation below 5% ( thickness greater than 0.5um ) |

|

|

Second layer |

The relative standard deviation below 10% ( thickness greater than 0.5um ) |

|

|

Spectral processing system |

|

|

Processor type |

Full digital 32-bit3 DSP |

|

|

The number of spectral channels |

256,512,1024,2048 choice |

|

|

Counting rate |

More than 100000cps |

|

|

Energy range |

500eV-40960eV |

|

|

Dead time |

<3% |

|

|

|

Light path system and sample observation |

|

|

Collimator system |

φ8mm*3φ2mmφ0.5mm Switchable |

|

|

Focusing system |

Laser focus |

|

|

Filter |

A variety of filter ( Ni, Cu, Mo, Al, Ti ) to choose |

|

|

Sample observation system |

The 3000000 pixel high-definition CCD camera, 20 times optical zoom. |

|

Sample room |

|

|

Sample room interior space(mm) |

(W x H x D):450×160×400mm |

|

|

Sample size |

(宽×深):250×275mm |

|

|

Sample table bearing weight |

≤5kg |

|

|

The test sample size |

W x H x D:440×150×390mm。 |

|

|

Sample table control |

Manual sample stage |

|

|

Work bench mobile |

X=200±5、Y=200±5、Z=160±5mm |

|

|

|

Computer and software |

|

|

|

Control computer |

Lenovo brand T4900V, 512MB memory, 80G hard disk |

|

|

|

Monitor |

Lenovo 17 inch LCD display |

|

|

|

Operating system |

WindowsXP、OEM simplified Chinese Edition |

|

|

|

Report results |

Word、Excel format |

|

|

|

Software |

RoHS detection software, coating thickness software, element analysis software |

|

|

|

Types of software |

Fundamental parameter method of FP software |

|

|

|

Software language |

Simplified Chinese, traditional Chinese, English, other |

|

|

|

Spectrum display |

Automatic peak qualitative, KLM markers, spectral overlapping comparison |

|

|

|

Spectral processing |

Total intensity, net intensity, background intensity; the whole area, net area, much element fitting, Gauss fitting; logarithmic spectrum |

|

|

|

Data analysis |

The basic parameters, basic pattern, without standard sample test, peak position correction, substrate amendment |

|

|

Weight and size |

|

|

The main body of the device size(mm) |

W 580×H 635×D 770mm |

|

|

Body weight |

About 60kg |

|

|

The environment of the use |

|

|

Working environment |

Temperature 15-250C,Humidity 40-70%RH |

|

|

Power supply system |

Single-phase 220V±10%,Working voltage in allowed range |

|

|

Other |

1. Don’t close to generate strong magnetic field, electric field, high frequency device

2. Reducing vibration

3. Less dust, low humidity, no corrosive gas

4. No direct sunlight

5. As the earthquake countermeasures, to consider the fixed device |

|

|

|

|

|

|

|

| |

|  | |  UTX650X ray fluorescence spectrometer UTX650X ray fluorescence spectrometer |  | | Product Name: UTX650X ray fluorescence spectrometer

Order number:

Optional accessories: no

Inquiry:

Detailed description

One, product introduction

UTX650 is an economy, practical, easy to operate by X ray fluorescence spectrometer, suitable for:

Hardware, connectors, electrical connector plating, plating, plastics, PCB, ABS magnesium alloy electroplating; content of ordinary alloy analysis. Plating bath analysis.

Coating thickness measurement

Hardware, connectors, electrical connector plating Au, Ag, Sn, Ni, Cu, Zn, Cr, NiP, SnPb, SnCu, ZnNi, AuPdNi such as alloy;

PCB Au, Ag Cu, electroplating, Ni, NiP, SnPb alloy

Plastic, ABS, magnesium alloy electroplating Au, Ag, Sn, Ni, Cu, Zn, Cr, NiP etc.

Alloy analysis

Stainless steel in Fe, Cr, Ni, Mo and other components

Brass Cu, Zn, Pb and other components

Copper in Cu, Zn, Sn, Pb and other components

Solder in the Sn, Pb and other ingredients

Plating bath analysis

Electroplating solution of Au, Ag, Cu, Ni, Cr, Zn, Sn concentration of main salt

Two, product characteristics

1, from K to U rapid element analysis, metal plating thickness detection

2, the detection sensitivity 0.01% to 100%; 0.02um to 40um coating

3, short measuring time, each measuring only 10-60 seconds

4, 15-20 times CCD color system was used for sample image observation

5, in a variety of shapes and specifications of the collimator can be chosen

6, a large window proportional counter, improve the stability of measurement

7, machinery and has the advantages of simple structure, reliable

8, FP basic algorithm software

9, the flexible application of analysis software

10, simple installation, fast instrument

Three, technical indicators

1, the implementation of product standards: DIN50987, ISO3497, ASTN.D568

2, the product parameters:

|

Measuring principle |

Energy dispersive X ray fluorescence analysis |

|

Determination of object |

Solid, liquid, powder |

|

Measuring function |

Single plating, alloy coating, coating thickness, most can be measured 5 layer; |

|

Elemental analysis ( material component analysis ) |

|

Plating bath analysis ( electroplating syrup main salt components analysis ) |

|

Measurement limit |

Coating thickness: 0.02um, elemental analysis: 100ppm |

|

Thickness measurement range |

0.02-40 um,(W、Au、Pb)10μm、(Cu、Zn、Ni、Cr、Sn)40um, |

|

Thickness measurement error |

The first layer is less than±5%,The second layer is less than±10%,The third layer is less than±15% |

|

Element analysis of measuring range |

Measuring element K19-U92, |

|

Test time |

Thickness measurement:10-60s,Element analysis:10-60s |

|

X ray generator part |

|

X light tube of origin and brand |

The United States of America (OXFORD) |

|

X ray tube target |

W target, Rh, Mo, Ag, Cr target optional |

|

X ray tube window |

Be |

|

Electrical parameters |

50W、4-50kV,0-1000uA |

|

Cooling mode |

Silicone grease cooling |

|

X ray irradiation |

↓X ray from top to bottom |

|

Radiation area |

Minimum spotφ0.1mm |

|

Service life |

15000-20000h |

|

Detector |

|

Detector of origin and brand |

The United States of America(LND) |

|

Cooling mode |

Electric refrigeration (-1900C) |

|

Resolution |

The Mn half peak width 760eV |

|

The detection window |

Be、Window area:400mm2 |

|

High-voltage power supply |

|

High voltage package of origin and brand |

The United States of America (SPELLMAN) |

|

Input voltage |

24VDC±10%、 |

|

Output voltage |

0-50kV、0-2.0mA,Output precision 0.01% |

|

Remarks |

Software automatic detection function |

|

Light path system |

|

Collimator system |

Single collimatorφ0.1mm、 |

|

Focusing system |

Laser focus |

|

Filter |

Multiple filter (Ni、Cu、Mo、Al、Ti) |

|

Sample observation system |

The 3000000 pixel high-definition CCD camera, 20 times optical zoom. |

|

Sample room |

|

Sample room interior space(mm) |

(W x H x D):450×160×400mm |

|

Sample size |

(WxD):250×275mm |

|

Sample table bearing weight |

≤5kg |

|

The test sample size |

W x H x D:440×150×390mm。 |

|

Sample table control |

Manual sample stage |

|

Work bench mobile technology data |

X=200±5、Y=200±5、Z=160±5mm |

|

A data processing system |

|

Control computer |

Lenovo brand M7150, 1G memory, 160G hard disk |

|

Monitor |

Lenovo 17 inch LCD Monitor |

|

Report results |

Word, PDF format |

|

Software |

Operating system:WindowsXP、OEM simplified Chinese Edition |

|

Coating thickness measurement software, element analysis software |

|

Software language |

Simplified Chinese, traditional Chinese, English, other |

|

Apparatus for packaging parameters |

|

The main body of the device size(mm) |

W580×H600×D715mm |

|

Body weight |

About 60kg |

|

The environment of the use |

|

Working environment |

Temperature 15-250C,Humidity 40-70%RH |

|

Power supply system |

Single-phase 220V±10%,Working voltage in allowed range |

|

Other |

1. Don’t close to generate strong magnetic field, electric field, high frequency device

2. Reducing vibration

3. Less dust, low humidity, no corrosive gas

4. No direct sunlight

5. As the earthquake countermeasures, to consider the fixed device |

| |

|  | |  Multi functional RoHS and Thickness Tester UTX850B Multi functional RoHS and Thickness Tester UTX850B |  | | Product Name: Multi functional RoHS and Thickness Tester UTX850B

Order number:

Optional accessories: no

Inquiry:

Detailed description

One, application field

UTX7850B is a versatile X ray fluorescence spectrometer, suitable for:

1, RoHS detection

The EU RoHS directive is restricted by the Cr, Hg, Pb, Cd, Br, Cl, I and other elements of the detection

2, coating testing

Suitable for testing the larger size of the hardware, connectors, electrical connector plating, plating, plastics, PCB, ABS magnesium alloy electroplating. Particularly suitable for thin Au, Ag, Pd and other precious metal plating.

Hardware, connectors, electrical connector plating Au, Ag, Sn, Ni, Cu, Zn, Cr, NiP, SnPb, SnCu, ZnNi, AuPdNi such as alloy;

PCB Au, Ag Cu, electroplating, Ni, NiP, SnPb alloy;

Plastic, ABS, magnesium alloy electroplating Au, Ag, Sn, Ni, Cu, Zn, Cr, NiP etc..

3, plating bath analysis

Electroplating solution of Au, Ag, Cu, Ni, Cr, Zn, Sn concentration was detected, and the impurity elements Ag, Cu, Ni, Cr, Zn, Sn, Fe, Co, Mn, Sb analysis.

4, alloy analysis

Stainless steel in Fe, Cr, Ni, Mo and other components

Alloy steel in Fe, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Nb, Mo, Sn, Sb, W, Pb and other components

Copper alloy in Cu, Zn, Fe, Cr, Ni, Cu, Zn, Sn, Sb, W, Pb, and other ingredients

Zinc alloy in Zn, Cu, Fe, Cr, Mn, Ni, Cu, Zn, Sn, Sb, Pb, W, and other ingredients

Solder in Sn, Fe, V, Cr, Ni, Cu, Zn, Nb, Sb, W, Pb and other components

5, precious metal identification

Gold jewelry testing purity and impurity Ag, Ni, Cu, Zn, Cd, Y, Zr, Rh, Pd analysis

Platinum jewelry testing purity and impurity Ag, Ni, Cu, Zn, Cd, Y, Zr, Rh, Pd, Au analysis

Palladium jewelry testing purity and impurity Ag, Ni, Cu, Zn, Cd, Y, Zr analysis

Silver jewelry testing purity and impurity Fe, Ni, Cu, Zn, Cd, Sn analysis

6, food and safety inspection

The daily food trace elements Fe, Ca, Zn, Cu, Pb, Cd, Ni analysis

Analysis of the effective components in various supplements such as Ca oral liquid on the content of Ca, Zn oral liquid on Zn content

Tea discrimination : according to the different origin of the trace elements in tea of different tea varieties, discrimination and authenticity

7, environment detection

Gasoline, diesel, kerosene and other content in Pb, As, Cd and other elements of the detection

Analysis of water quality analysis, water, sewage, river water, groundwater, drinking water Fe, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Nb, Mo, Sn, Sb, W, Pb, Hg, Cd and other elements

Two, product characteristics

1, from Al to U rapid element analysis, metal plating thickness detection

In 2, the detection sensitivity of 1ppm 99.99%; 0.005um to 35um coating

In 3, 15-20 times CCD color system was used for sample image observation

4, in a variety of shapes and specifications of the collimator can be chosen

In 5, a variety of filtering mechanism, a variety of specifications of filters for different samples

In 6, high resolution of SIPIN detector, improve the measurement sensitivity

In 7, the detector of electric refrigeration, without liquid nitrogen

In 8, large sample chamber with precision regulating electric sample table, can measure large to small samples of various sizes

In 9, FP basic algorithm software

In 10, the flexible application of analysis software

11, simple installation, fast instrument

Three, technical indicators

|

|

Measuring principle |

Energy dispersive X ray fluorescence analysis |

|

|

|

Determination of object |

Solid, liquid, powder |

|

|

|

Measuring function |

RoHS detection, detection of halogens ( Cl, Br, I, Br ), qualitative and quantitative |

|

|

|

Single plating, alloy coating, coating thickness, most can be measured 3 layer |

|

|

|

Elemental analysis ( material component analysis ) |

|

|

|

Plating bath analysis ( electroplating syrup main salt components analysis ) |

|

|

|

Measurement limit |

Thickness:0.01 um,Element analysis:2ppm,RoHS:2ppm |

|

|

|

Thickness measurement range |

0.01-35 um,(W、Au、Pb)10um、(Cu、Zn、Ni、)35um, |

|

|

|

Thickness measurement error |

The first layer is less than 3%, the second layer is less than 8%, the third layer is less than 12% |

|

|

|

Element analysis of measuring range |

Al19-U92 |

|

|

|

RoHS test range |

2ppm-99.99% |

|

|

|

RoHS test precision |

The relative standard deviation below 5% ( content greater than 500 ppm ) |

|

|

|

The RoHS test accuracy |

Relative error below 5% ( content greater than 500 ppm ) |

|

|

|

Test time |

Thickness:10-60s,Element analysis:10-60s,RoHS:200s |

|

|

High-voltage power supply |

|

|

High voltage package of origin and brand |

The United States of America ( SPELLMAN ) |

|

|

Input voltage |

24VDC±10% |

|

|

Output voltage |

0-50kV |

|

|

Output current |

0-2.0mA |

|

|

Output precision |

0.01% |

|

|

Remarks |

Software automatic detection function |

|

|

X ray tube |

|

|

X light tube of origin and brand |

The United States of America ( OXFORD ) |

|

|

X ray tube target |

W target, Rh, Mo, Ag, Cr target optional |

|

|

X ray tube window |

Be window |

|

|

Electrical parameters |

50W、4-50kV,0-1000uA |

|

|

Cooling mode |

Silicone grease cooling |

|

|

Service life |

15000-20000h |

|

|

Detector |

|

|

Detector of origin and brand |

The United States of America ( AMPTEK ) |

|

|

Detection range |

Al19-U92 |

|

|

Resolution |

FWHM 139eV |

|

|

The detection window |

Be,Window area:5-25mm2 |

|

|

Thickness |

0.5-5mm |

|

|

Cooling mode |

Electric refrigeration |

|

|

RoHS measuring index |

|

|

Analysis range |

1ppm—99.99% |

|

|

Precision |

The relative standard deviation below 5% ( content is greater than 500ppm ) |

|

|

Degree of accuracy |

Relative error below 5% ( content is greater than 500ppm ) |

|

|

Thickness indicator |

|

|

Analysis range |

0.01um—35um |

|

|

The first layer |

The relative standard deviation below 3% ( thickness greater than 0.5um ) |

|

|

Second layer |

The relative standard deviation below 8% ( thickness greater than 0.5um ) |

|

|

Third layer |

The relative standard deviation below 12% ( thickness greater than 0.5um ) |

|

|

Spectral processing system |

|

|

Processor type |

Full digital 32-bit3 DSP |

|

|

The number of spectral channels |

256,512,1024,2048 choice |

|

|

Counting rate |

More than 100000cps |

|

|

Energy range |

500eV-40960eV |

|

|

Dead time |

<3% |

|

|

|

Light path system and sample observation |

|

|

Collimator system |

φ8mm*3φ2mmφ0.5mm Switchable |

|

|

Focusing system |

Laser focus |

|

|

Filter |

A variety of filter ( Ni, Cu, Mo, Al, Ti ) to choose |

|

|

Sample observation system |

The 3000000 pixel high-definition CCD camera, 20 times optical zoom. |

|

Sample room |

|

|

Sample room interior space(mm) |

(W x H x D):450×90×400mm |

|

|

Sample size |

(宽×深):250×275mm |

|

|

Sample table bearing weight |

≤5kg |

|

|

The test sample size |

W x H x D:440×80×390mm。 |

|

|

Sample table control |

High precision automatic sample stage |

|

|

Work bench mobile |

X=200±5、Y=200±5、Z=160±5mm |

|

|

Worktable moving precision |

0.005mm |

|

|

|

Computer and software |

|

|

|

Control computer |

Lenovo brand M7150,1G memory, 160G hard disk |

|

|

|

Monitor |

Lenovo 17 inch LCD display |

|

|

|

Operating system |

WindowsXP、OEM simplified Chinese Edition |

|

|

|

Report results |

Word、Excel format |

|

|

|

Software |

RoHS detection software, coating thickness software, element analysis software |

|

|

|

Types of software |

Fundamental parameter method of FP software |

|

|

|

Software language |

Simplified Chinese, traditional Chinese, English, other |

|

|

|

Spectrum display |

Automatic peak qualitative, KLM markers, spectral overlapping comparison |

|

|

|

Spectral processing |

Total intensity, net intensity, background intensity; the whole area, net area, much element fitting, Gauss fitting; logarithmic spectrum |

|

|

|

Data analysis |

The basic parameters, basic pattern, without standard sample test, peak position correction, substrate amendment |

|

|

Weight and size |

|

|

The main body of the device size(mm) |

W 580×H 635×D 770mm |

|

|

Body weight |

About 80kg |

|

|

The environment of the use |

|

|

Working environment |

Temperature 15-250C,Humidity 40-70%RH |

|

|

Power supply system |

Single-phase 220V±10%,Working voltage in allowed range |

|

|

Other |

1. Don’t close to generate strong magnetic field, electric field, high frequency device

2. Reducing vibration

3. Less dust, low humidity, no corrosive gas

4. No direct sunlight

5. As the earthquake countermeasures, to consider the fixed device |

|

|

|

|

|

|

|

| |

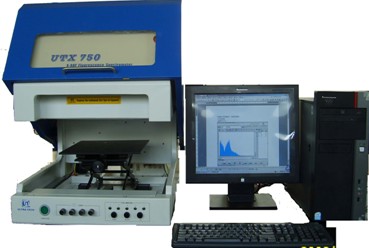

|  | |  X ray fluorescence spectrometer UTX750 X ray fluorescence spectrometer UTX750 |  | | Product Name: X ray fluorescence spectrometer UTX750

Order number:

Optional accessories: no

Inquiry:

Detailed description

One, Product brief introduction

UTX750 is a versatile X ray fluorescence spectrometer, suitable for:

In 1, RoHS detection

The EU RoHS directive is restricted by the Cr, Hg, Pb, Cd, Br, Cl, I and other elements of the detection

2, plating bath analysis

Electroplating solution of Au, Ag, Cu, Ni, Cr, Zn, Sn concentration was detected, and the impurity elements Ag, Cu, Ni, Cr, Zn, Sn, Fe, Co, Mn, Sb analysis.

3, alloy analysis

Stainless steel in Fe, Cr, Ni, Mo and other components

Alloy steel in Fe, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Nb, Mo, Sn, Sb, W, Pb and other components

Copper alloy in Cu, Zn, Fe, Cr, Ni, Cu, Zn, Sn, Sb, W, Pb, and other ingredients

Zinc alloy in Zn, Cu, Fe, Cr, Mn, Ni, Cu, Zn, Sn, Sb, Pb, W, and other ingredients

Solder in Sn, Fe, V, Cr, Ni, Cu, Zn, Nb, Sb, W, Pb and other components

4, precious metal identification

Gold jewelry testing purity and impurity Ag, Ni, Cu, Zn, Cd, Y, Zr, Rh, Pd analysis

Platinum jewelry testing purity and impurity Ag, Ni, Cu, Zn, Cd, Y, Zr, Rh, Pd, Au analysis

Palladium jewelry testing purity and impurity Ag, Ni, Cu, Zn, Cd, Y, Zr analysis

Silver jewelry testing purity and impurity Fe, Ni, Cu, Zn, Cd, Sn analysis

5, food and safety inspection

The daily food trace elements Fe, Ca, Zn, Cu, Pb, Cd, Ni analysis

Analysis of the effective components in various supplements such as Ca oral liquid on the content of Ca, Zn oral liquid on Zn content

Tea discrimination : according to the different origin of the trace elements in tea of different tea varieties, discrimination and authenticity

6, environment detection

Gasoline, diesel, kerosene and other content in Pb, As, Cd and other elements of the detection

Analysis of water quality analysis, water, sewage, river water, groundwater, drinking water Fe, Ti, V, Cr, Mn, Co, Ni, Cu, Zn, Nb, Mo, Sn, Sb, W, Pb, Hg, Cd and other elements

Two, product characteristics

1, the detection sensitivity of 2ppm to 99.99%

2, 15-20 times CCD color system was used for sample image observation

3, in a variety of shapes and specifications of the collimator can be chosen

4, a variety of filtering mechanism, a variety of specifications of filters for different samples

5, high resolution of SIPIN detector, improve the measurement sensitivity

6, the detector of electric refrigeration, without liquid nitrogen

7, large sample storehouse, can measure large to small samples of various sizes

8, FP basic algorithm software

9, the flexible application of analysis software

10, simple installation, fast instrument

Three, technical indicators

|

High-voltage power supply |

|

|

Input voltage |

24VDC±10% |

|

|

Output voltage |

0-50kV |

|

|

Output current |

0-2.0mA |

|

|

Output precision |

0.01% |

|

|

Remarks |

Software automatic detection function |

|

|

X ray tube |

|

|

X ray tube target |

W target, Rh, Mo, Ag, Cr target optional |

|

|

X ray tube window |

Nylon window |

|

|

Electrical parameters |

50W、4-50kV,0-1000uA |

|

|

Cooling mode |

Electric refrigeration |

|

|

Service life |

15000-20000h |

|

|

Detector |

|

|

Detection range |

Al19-U92 |

|

|

Resolution |

FWHM 139eV |

|

|

The detection window |

Be,Window area:5-25mm2 |

|

|

Thickness |

0.5-5mm |

|

|

RoHS measuring index |

|

|

Analysis range |

1ppm—99.99% |

|

|

Precision |

The relative standard deviation below 5% ( content is greater than 500ppm ) |

|

|

Degree of accuracy |

Relative error below 5% ( content is greater than 500ppm ) |

|

|

Spectral processing system |

|

|

Processor type |

Full digital 32-bit3 DSP |

|

|

The number of spectral channels |

256,512,1024,2048 choice |

|

|

Counting rate |

More than 100000cps |

|

|

Energy range |

500eV-40960eV |

|

|

Dead time |

<3% |

|

|

|

Light path system and sample observation |

|

|

Collimator system |

φ8mm*3φ2mmφ0.5mm Switchable |

|

|

Focusing system |

Laser focus |

|

|

Filter |

A variety of filter ( Ni, Cu, Mo, Al, Ti ) to choose |

|

|

Sample observation system |

The 3000000 pixel high-definition CCD camera, 20 times optical zoom. |

|

Sample room |

|

|

Sample room interior space(mm) |

(W x H x D):450×160×400mm |

|

|

Sample size |

(宽×深):250×275mm |

|

|

Sample table bearing weight |

≤5kg |

|

|

The test sample size |

W x H x D:440×150×390mm。 |

|

|

Sample table control |

Manual sample stage |

|

|

Work bench mobile |

X=200±5、Y=200±5、Z=160±5mm |

|

|

|

Computer and software |

|

|

|

Control computer |

Lenovo brand T4900V, 512MB memory, 80G hard disk |

|

|

|

Monitor |

Lenovo 17 inch LCD display |

|

|

|

Operating system |

WindowsXP、OEM simplified Chinese Edition |

|

|

|

Report results |

Word、Excel format |

|

|

|

Software |

RoHS detection software, coating thickness software, element analysis software |

|

|

|

Types of software |

Fundamental parameter method of FP software |

|

|

|

Software language |

Simplified Chinese, traditional Chinese, English, other |

|

|

|

Spectrum display |

Automatic peak qualitative, KLM markers, spectral overlapping comparison |

|

|

|

Spectral processing |

Total intensity, net intensity, background intensity; the whole area, net area, much element fitting, Gauss fitting; logarithmic spectrum |

|

|

|

Data analysis |

The basic parameters, basic pattern, without standard sample test, peak position correction, substrate amendment |

|

|

Weight and size |

|

|

The main body of the device size(mm) |

W 580×H 635×D 770mm |

|

|

Body weight |

About 60kg |

|

|

The environment of the use |

|

|

Working environment |

Temperature 15-250C,Humidity 40-70%RH |

|

|

Power supply system |

Single-phase 220V±10%,Working voltage in allowed range |

|

|

Other |

1. Don’t close to generate strong magnetic field, electric field, high frequency device

2. Reducing vibration

3. Less dust, low humidity, no corrosive gas

4. No direct sunlight

5. As the earthquake countermeasures, to consider the fixed device |

|

|

|

|

|

|

|

| |

|

|

|

Total:10Records Page:1/2 5records/page

1 [2]: |

|

|

|

|

|

|

|